Introduction

Silicon photonic integrated circuits (PICs) tend to lie at the heart of the communications revolution owing to the low power consumption, high speed, large bandwidth, and complementary metal-oxide semiconductor (CMOS) compatibility. Phase shifter, as a fundamental photonic device for achieving phase tuning, require large-scale integration in applications such as optical phased arrays, optical neural networks, and integrated photonics quantum systems. Thermal-optic phase shifter, which utilizes a microheater to heat waveguide for phase tuning, offers the advantages of ease of fabrication, low cost, and compact structures, and has been widely employed in large-scale PICs. However, conventional metal-based microheaters used for thermal-optic tuning require thick insulation layers to avoid absorption losses, resulting in high power consumption and low response speeds, which limit their suitability for applications requiring fast-response thermal-optic tuning. Emerging 2D material microheaters face the challenge of complex preparation and transfer processes, resulting in low yield in practical applications.

Recently, a collaborative effort between the team of Prof. Xinliang Zhang and Prof. Jianji Dong and the team of Prof. Bin Hu from Huazhong University of Science and Technology introduced a thermal-optic phase shifter based on a hydrogen-doped indium oxide (IHO) microheater. This novel device achieved high efficiency, fast response, and low-loss thermal-optic tuning on a silicon-on-insulator (SOI) substrate. Experimental demonstrations showcased a remarkable response time of 970 ns/980 ns (rise time/fall time), a corresponding measurement bandwidth of 385 kHz, a π phase shift power consumption of 9.6 mW, and an insertion loss of approximately 0.5 dB. The related work, titled An Efficient, Fast-Responding, Low-Loss Thermo-Optic Phase Shifter Based on a Hydrogen-Doped Indium Oxide Microheater, was published online on June 29th in the journal Laser & Photonics Reviews.

Research Highlights

Figure 1. The structure of the thermal-optic phase shifter based on the IHO microheater.

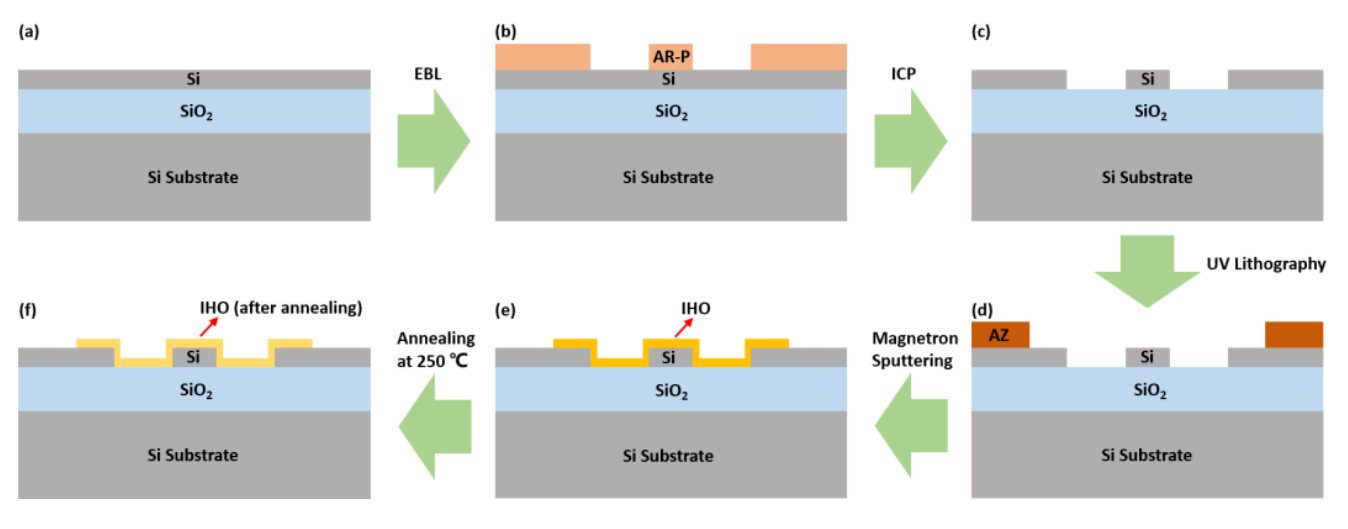

Figure 2. The fabrication process of the thermal-optic phase shifter based on the IHO microheater.

To achieve a thermal-optic phase shifter with excellent thermal-tuning parameters and a mature integration fabrication process, as shown in Figure 1, this study proposes a scheme that involves directly covering the silicon waveguide with IHO material for thermal tuning. Due to its high mobility and low carrier concentration, the IHO material exhibits high conductivity and high transparency in the near-infrared band. Consequently, it can be directly overlaid on silicon waveguides as a microheater while introducing low losses. Furthermore, as illustrated in Figure 2, the IHO material's magnetron sputtering growing process at room temperature allows for its patterning through the mature lift-off technique, facilitating high-precision large-scale integration. Through experimental testing, our phase shifter has demonstrated advantages such as low power consumption (9.6 mW), fast response (970 ns/980 ns), and low insertion loss (≈0.5 dB). The stable and mature fabrication process of the phase shifter offers significant advantages for further development of large-scale integrated systems.

Figure 3. The experimental results of the thermal-optic phase shifter based on the IHO microheater.

Conclusion and Outlook

This work achieved an efficient, fast-responding, and low-loss thermal-optic phase shifter based on an IHO microheater directly covering waveguide. The growing and patterning of the IHO microheater can be achieved through mature magnetron sputtering and delamination processes, respectively, which holds promise for application in large-scale integrated photonics systems.

This research was supported by the Natural Science Foundation of China (U21A20511, 62274071), the National Key Research and Development Program of China (2022YFB2804200), and the Innovation Project of Optics Valley Laboratory (Grant No. OVL2021BG001). Prof. Jianji Dong and Prof. Bin Hu are the corresponding authors of the paper, and Weiyu Tong and Erqi Yang are the co-first authors.

Paper Link: https://doi.org/10.1002/lpor.202201032